The Future of Wood: 3D Printing Potential and Environmental Impact

Written on

Chapter 1: Innovations in Lab-Grown Wood

Recent advancements have emerged in the field of synthetic wood production, raising questions about the future of traditional timber. In May, a team of researchers at MIT unveiled an exciting breakthrough: the ability to cultivate wood in a laboratory setting. This wood is not only lab-grown but also can be shaped through 3D printing technology.

The implications of this development are vast. Could we eliminate the need for cutting down billions of trees annually for construction, furniture, and paper products? The short answer is no, as there are numerous challenges that need to be addressed. However, this is a significant first step toward a sustainable future.

Section 1.1: The Lab's Wood Production Process

To understand the process, let’s delve into what the researchers achieved. They utilized cells from the Zinnia elegans plant, commonly known as the common zinnia. This flowering plant is often found in gardens and floral arrangements.

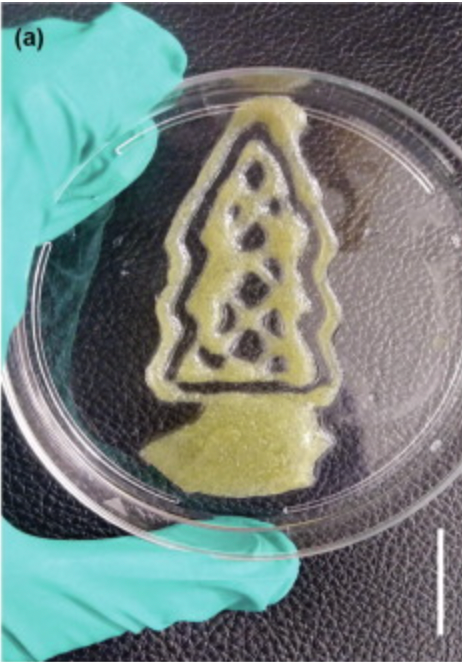

From the zinnia leaves, the team extracted plant cells and treated them with a specific hormone mixture to foster growth in a liquid environment. After several days, the cells were placed in a nutrient-rich gel and extruded into predetermined two-dimensional designs on Petri dishes. These dishes were then sealed and kept in darkness for two months to encourage nutrient utilization without the cells attempting to photosynthesize.

Following this incubation, the researchers examined the resulting structures, aiming to observe lignification—the development of lignin, a critical polymer that imparts strength and stability to wood. Their findings revealed varying degrees of lignification, influenced by the hormone levels used. The resultant material exhibited stiffness comparable to certain soft woods, with flexibility adjustable based on hormone concentration.

However, can we fully replace traditional wood production? Not quite, as several obstacles remain.

Section 1.2: Challenges in Lab-Made Wood

The visual evidence from the researchers' findings indicates that we are still far from replacing the lumber industry entirely. Some critical challenges include:

- Thickness Limitations: The maximum thickness achieved in the gel was only 2.5 millimeters. While experiments showed growth with additional layers of gel, significant thickness remains a challenge.

- Dimensional Constraints: The current outputs are strictly two-dimensional. Although the gel solidifies at room temperature post-extrusion, it may not maintain integrity in three dimensions.

- Hardness Comparisons: The most robust lab-created products demonstrated a storage modulus of around 400 MPa, in stark contrast to the approximately 1,200 MPa for hardwoods, making them softer and less stable.

- Scalability Issues: The largest structures produced so far are mere inches long, which raises concerns about the feasibility of generating larger lumber pieces.

- Plant Species Variability: Zinnia plants do not naturally produce wood-like materials, suggesting that different plant species might require tailored hormone treatments for effective results.

- Environmental Impact of Hormones: The production of the hormone mixtures necessary for growth may be more resource-intensive and environmentally detrimental than simply harvesting trees from sustainably managed forests.

While lab-grown wood could contribute to reducing deforestation, it is unlikely to supplant traditional timber anytime soon. Moreover, the carbon-sequestering benefits of naturally grown trees could be compromised by the production methods of lab-made alternatives.

Chapter 2: The Future of 3D Printed Wood

The first video, "Can you 3D Print on Wood?" explores the potential of 3D printing technology in the context of wood production and its implications for the future.

The second video, "Simulating Wood and Metal with a 3D Printer," examines advancements in 3D printing that mimic the properties of wood and metal, providing insight into the future of materials.

In summary, while the innovation of lab-grown wood showcases the exciting intersection of 3D printing and biological cultivation, it is essential to recognize the limitations and challenges that still exist. The quest to create sustainable alternatives to traditional timber is ongoing, and the journey ahead is likely to be complex and multifaceted.